What Is Inventory Management In Supply Chain: A To Z Guide

Do you want to know what is inventory management in supply chain? Then, first, you have to know about inventory management and supply chain.

In simple words, inventory management means managing inventory in a structured way. This process is crucial for businesses to operate smoothly, make timely procurements, and improve productivity. On the other hand, inventory management in the supply chain refers to an effective inventory management system for managing these business processes.

In this article, I will outline what is inventory management in supply chain, its importance, benefits, processes, techniques and how to choose the best inventory management system to upgrade your business.

What is Inventory Management in Supply Chain?

Inventory management is the entire process of supervising inventory and stock items, such as ordering, storing, using, and selling. The primary purpose of inventory management is the management of raw materials, finished products, and components, along with warehousing and moving from these facilities to the point of sale.

There are numerous types of inventory management, and each method has pros and cons based on the company's needs.

Example of Inventory Management

For example, if an electronics vendor supplies PCs, laptops, soundboxes, hard drives, UPS, and other accessories to offices, the supplies products are considered inventory.

An example of inventory management is the regular practice of monitoring the stock level of inventory, analyzing sales data, and placing orders with suppliers to replenish inventory.

Any business can use inventory management to track its flow of goods. The key module of this inventory management is to keep a detailed record of each product as it supervises enters, leaves, or warehousing or point of selling products.

Why is Inventory Management Important in the Supply Chain?

The objectives of inventory management in the supply chain are crucial for a variety of distinct aspects. As a component of the supply chain, effective inventory management is a centralized hub where all supply chain links are connected.

By inventory management, you can track stock and monitor sales data regularly, which will help you avoid overstock, stock errors, and other problems. However, the importance of inventory management in the supply chain is the following:

-

Purchasing & Supervising Inventory

Inventory management supervises and controls the total amount of inventory they have coming in and going out. Besides, it enables businesses to balance the whole amount of selling products, maintaining the storage facilities, and fulfilling the orders. The more a company can control its inventory, the more it can save money from its operations.

-

Storing Inventory

In addition, when a business has overstock, it can face money tied up, limiting cash flows and budget deficit, etc. An inventory management system can help companies balance between being under and overstocked for optimal profitability.

-

Business Growth from Inventory Management

Moreover, inventory management can fulfill customers' experience with their expectations, assuring loyalty and continued patronage of the company. It also encourages customers to remain loyal and deliver their orders timely. So, enterprises need inventory management to expand their business.

-

Profits from Inventory Management

An inventory management system for the food and health industry and other businesses helps to prevent the accumulation of surplus goods at the business and fulfill clients' requirements.

A comprehensive, accurate, and timely inventory management system can improve your business with the best customer satisfaction and success.

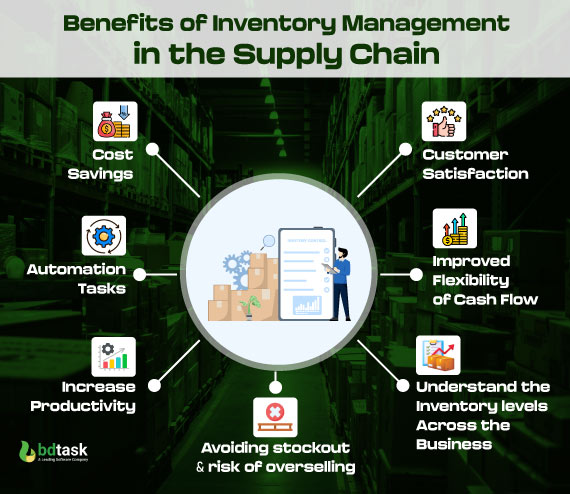

Benefits of Inventory Management in the Supply Chain

Inventory management is the key to running a successful business. The role of inventory management in the supply chain system is to ensure smooth business operations, balance demand with supply parameters, and customer satisfaction.

Companies can avoid stockouts by maintaining optimal inventory levels that lead to dissatisfied customers or low sales while also minimizing the holding costs related to excess stock. The advanced benefits of inventory management are the following:

-

Customer Satisfaction

Excellent inventory management practices help businesses ensure that products are available and can be delivered without dissatisfaction to customers and end users.

- Cost Savings

The main objective of inventory management is to know how many products are being stored and available for selling. It can enable businesses to ensure unsold stock, provide fulfillment of customer satisfaction, and even minimize or eliminate from the inventory management equation to allow cost-efficient operations. Because unsold stock costs money, holding carrying costs like transportation fees, employee salaries, and insurance.

-

Improved Flexibility of Cash Flow

This management ensures organizations that they can maximize their cash flow capabilities by balancing between coming new products and moving sell products.

-

Understand the Inventory levels Across the Business

An ERP system provides an end-to-end view of orders through all departments. Besides, centralized purchasing can reduce duplication when replenishing stock and having the ability to purchase more by cost savings. Further benefits get abandoned when implementing your inventory software with accounting and back-office processes.

-

Automation Tasks

The significant benefits of this Barcode and RFID scanning can boost stock tracking, receiving, and fulfillment. Using inventory management software reduces errors made by employees and manual entries.

-

Increase Productivity

Effective inventory management in the supply chain saves time, so it creates free time and concentrates on other activities.

-

Avoiding stockout and risk of overselling

A complete guide to inventory management helps businesses to count inventory stock to avoid out-of-stock and over-carrying inventory issues. It enables you to track what's in stock and what's on backorder so you can keep products from overselling.

Types of Inventory Management: Method of Inventory Management in Supply Chain

What is inventory management in supply chain, has a part of different types of Inventory management that help to manage particular businesses. The types of inventory management differ based on the type of business. The suitable types of inventory management depend on the company's needs. The following is a different type of inventory management in the supply chain, including their uses and advantages:

Raw Materials

The components that are used for making products are considered raw materials. Generally, raw materials are divided into two categories. Direct materials are directly used as part of final products. Further, indirect raw materials help make final products but are not used in finished products.

For example, pizza dough ingredients are the direct raw material and the fuel needed to run industries' woodfires to make pizza. A company might produce, extract, order, or supply raw materials from a supplier.

Just-in-Time Management (JIT)

Just-in-time inventory management is the most effective method aimed at saving significant money, reducing waste, and maintaining product availability. With JIT inventory management, the company receives goods from suppliers when needed for production.

This type of inventory helps to reduce storage and insurance costs while discharging surplus inventory. However, the best part of JIT is it reduces the storage space for inventory, the risk of overstocking or stockouts, and minimizes inventory holding costs.

Materials Requirement Planning (MRP)

The material Requirement Planning (MRP) system helps you manage the manufacturing process by calculating the quantity of materials needed for production. With the MRP system, businesses can plan and schedule production effectively.

It is an ideal systematic inventory management that ensures raw materials are available on time when needed and helps to complete customers' orders and demands on time. However, MRP allows business to optimize their business process, minimizing inventory holding costs and scheduling production.

Work-in-Progress Inventory

Work-in-process, also called goods-in-process, refers to when raw materials are transformed into finished products in the process of production. In simple words, this inventory consists of all work-in-progress items that have been processed but don't go for sale.

For example, coffee beans that have been roasted and waiting for packaging. Before packaging, they go for a quality check, which is considered a work in progress.

This type of inventory needs extra care as they are essential for balance. Storing too much WIP inventory will increase carrying costs and result in tied cash flows. Again, poor WIP could cause failure to demand customer orders.

However, with this inventory, you can easily track your production metrics like speed and frequency. Also, you can use these data for more accurate forecasting.

Finished Goods

Finished goods are final products that are waiting to be sold. The quantity of finished goods that businesses have stocked depends on other inventory management methods.

For example, following the JIT inventory method, manufacturers will produce and assemble goods that they needed rather than carrying over WIP and finished goods.

Inventory Management Process in Step-by-Step

Inventory management in the supply chain requires several processing steps to work together for effective and successful inventory management. However, inventory management includes the following steps:

- Demand Forecasting

The first step of inventory management is to predict the demand for the product based on historical data and purchasing trends. With this step, a company can assume how much inventory they need and minimize stockouts and overstocking.

- Tracking Inventory

You should track the accuracy of your inventory levels and have a clear picture of them. Keep an eye on your stock levels in real-time using manual tracking and barcode scanning and be able to decide when to place a new order.

- Receive and Audit the Product

Receiving orders from suppliers is following the steps of inventory management. After receiving the products, you should audit the product quantity, serial code, barcode scanning, and temperature condition.

- Quality Control

You must ensure the quality of your products before being stored or making them sell. Be sure about the satisfactory quality of inventory, damage, and defect-free.

- Reorder and Restock New Inventory management

The inventory management process requires a timing reorder process, and restocking new inventory is crucial for minimizing both the risk of stockouts and deadstock and saving time and any mistakes of human error.

- Proper Storing Inventory

Following receiving editing and quality checks, inventory should be in an accessible, arranged, and well-stored place to minimize damage and ensure quality.

Inventory Management Techniques in Supply Chain

The best inventory management system involves utilizing numerous techniques and terms depending on the type of business or products being analyzed to fulfill customer demand and operate profitably. Among other methods, here are the four most commonly used inventory management techniques include:

- ABC Analysing

ABC analysis inventory management method classifies inventory into three categories. Category A indicates high-value items and, accordingly, B for moderate and C for low-value items. Each category is managed separately by the inventory management system.

Days Sales of Inventory (DSI)

DSI indicates the average time in days that a company takes to turn its inventory. Further, it suggests the liquidity of the inventory represents how many days a company's current inventory stock will last. Generally, a lower DSI level is preferred as it indicates a shorter period to clear off the inventory than the average DSI.

Economic Order Quantity (EOQ)

The EOQ model is used to calculate the number of units a company should add to its inventory with each other to reduce the total cost of the inventory management system in the supply chain, assuming customers demand spontaneously. In addition, this model ensures that the right amount of inventory is ordered per batch so that a company doesn't need an immediate inventory order.

Minimum Order Quantity (MOQ)

A company relies on a minimum order quantity that will order minimum amounts of goods from suppliers to keep each order at low costs. MOQ can impact inventory management decisions, mainly when dealing with limited store space or low-demand items.

How to Choose the Right Inventory Management System in the supply Chain?

Choosing the inventory management system is a critical decision for a business. Otherwise, a backward business plan without an inventory management system can lead to increased holding costs, overstocking, stockouts, tied-up cash flow, and dissatisfied customers. 75% of organizations suffer from lost sales due to poor inventory control methods.

Here are some essential factors you need to consider when selecting the best inventory management system for your business:

- Business Size and Type

Business types, sizes, and operating processes should be considered to select the best inventory management process. Larger companies with complex supply chains need advanced and sophisticated inventory management systems, while small businesses can choose a simple inventory management approach.

- Existing Inventory Management Software

If you already have inventory management software and are searching for new inventory management software, then your new software must be integrated with the existing software and supply chain.

- Pricing

For a new inventory management system, you should determine the ongoing and upfront costs of this system, such as maintenance, training costs, and license fees, and it is priceworthy.

- Features and Functions

The requirements of your business should be cleared, such as forecasting and demand planning, real-time inventory tracking, barcode scanning, and integration with other companies. All of the requirements should be considered when choosing inventory management.

- Easy User Interface

Choose an easy interface inventory management system so that staff members can easily access the software. The system should be intuitive and user-friendly for all employees and management.

So, considering these factors, a business can choose its inventory management system and software to achieve its goals and needs.

Disadvantages of Inventory Management in the supply chain

Every system has some demerits, and inventory management software has little, too. If companies take some precautions, they can mitigate these troubles. The disadvantages of inventory management systems are the following:

- Impersonal Touch

Inventory management systems lack a personal touch because of automated operations.

- Complexity to Handle

Some methods and strategies of inventory management can be complicated for business staff.

- Expensive Implementation

The implementation cost of inventory management software can be expensive for small businesses. However, this investment is for one time, and instead of it, companies can increase profit and improve their loyalty.

- Risk of Malicious Attacks and System Crashes

Malicious attacks and software crashes are risks to all businesses. The Internet of Things (IoT) can also create problems. Cloud-based software typically has the best security, but the breach attacks would arise from vendors.

Automate Your Business Process with the Wholesale-Inventory Management System

Wholesale-Inventory Management System provides cloud-based inventory management solutions for any business type and size. This inventory management system can make a business successful, productive, effective, and lower expenses.

However, this inventory management software offers an easy inventory management system to boost your profit. Besides, it controls features, including account, purchase, and supply chain management, CRM and stock management system, real-time report cashflow management system, automated stock replenishment, and Data synchronizer $ settings.

Discover more about how you can use ‘Wholesale - Inventory Management System’ to conduct your business automatically, reducing costs and increasing cash flow.

More than 200 businesses worldwide are using this inventory management system with satisfaction. You can rationally customize your inventory system. Utilize the benefits of this inventory management software to create a robust inventory management system for your business.

The Verdict

Inventory management is a crucial system for a business's profitability, customer feedback, and longevity. Hope, 'What is inventory management in supply chain' refers to a complete guideline about the inventory management process for your business. This business management process is a competitive advantage in today's world of eCommerce. Successful inventory management will help you reduce business costs, including transport costs, warehouse costs, and spoilage costs.